CAMLOG® SCREW-LINE implant Promote® plus 6.0x11

The CAMLOG® Implant types SCREW-LINE are manufactured with the latest state-of-the-art technology. The very heart of the system is the Tube-in-Tube® Implant-abutment connection. Its precision and the special geometric principle with three grooves and cams ensures almost perfect force and torque distribution.

| Material | Grade 4 Titanium |

| Surface | Promote+ |

| Addendum | Snap-in |

Globally recognized product - proven millions of times

The CAMLOG® implant system is scientifically well documented and the studies have shown excellent results. The SCREW-LINE implant type have been successful in international markets for many years. At the heart of the system is the Tube-in-Tube® connection between the implant and the abutment. Its precision and special geometric principle with three cams and grooves ensure excellent force and torque distribution.

Advantages of the CAMLOG system at a glance

- Consistently prosthetic-oriented implant system

- High precision CAMLOG® Tube-in-Tube® connection

- Excellent long-term results

- Comprehensive scientific documentation

- Platform Switching option

Diameter of implants

Length of implants

PROMOTE® surface

CAMLOG® SCREW-LINE implants have a Promote® surface. This abrasive-blasted and acid-etched surface extends to a smoothly turned strip on the neck edge of the implant, which is 1.4 mm wide for the Promote® surface CAMLOG® SCREW-LINE implant, and for the Promote® plus surface CAMLOG® SCREW-LINE implant, 0.4 mm.

Promote® surface has been shown to be excellent for securing dental implants in bone with bone histological and biomechanical scientific studies. These results demonstrate that the Promote® surface allows for rapid and safe osseointegration of CAMLOG® implants.

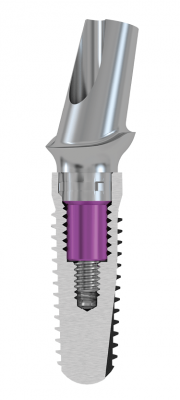

CAMLOG® Tube-in-Tube® implant abutment connection

At the heart of the CAMLOG® implant system is the innovative implant-abutment connection - the Tube-in-Tube® (“tube-in-tube”).

This precise, non-rotating form fit allows for easy and long-lasting prosthetic rehabilitation from the individual crown to the bridge, or even a long-lasting, secure screw-mounted restoration.

The shape fitting and the connection of specially arranged cams and grooves in the Tube in Tube® design allow for an optimal distribution of the forces acting on the joint. The screw securing the abutment barely receives any load, its function is only the vertical fastening. Thus, loosening or breaking of the screw can be largely ruled out.

These excellent properties are confirmed by clinical experience.

Internal thread and external geometry of the CAMLOG® implant

In the inner wall of the implant, which is designed for Tube-in-Tube® connection, each 3.8 / 4.3 / 5.0 / 6.0 mm outer diameter CAMLOG® implant is provided with an upper internal screw thread into which the gingiva former can be screwed (Fig. 3, for implants with a diameter of 3 mm, there is only a lower internal thread). Below this, in the apical direction, there is an M 1.6 or M 2.0 thread second internal screw thread (for CAMLOG® abutment and fixing screw).

When implanting the implant, one of the grooves inside the implant must be in the vestibular direction in order for the abutment to be positioned optimally. The markings on the outside of the insertion tools used for CAMLOG® SCREW-LINE implants correspond to the position of the grooves inside the implant.

Surgical kit

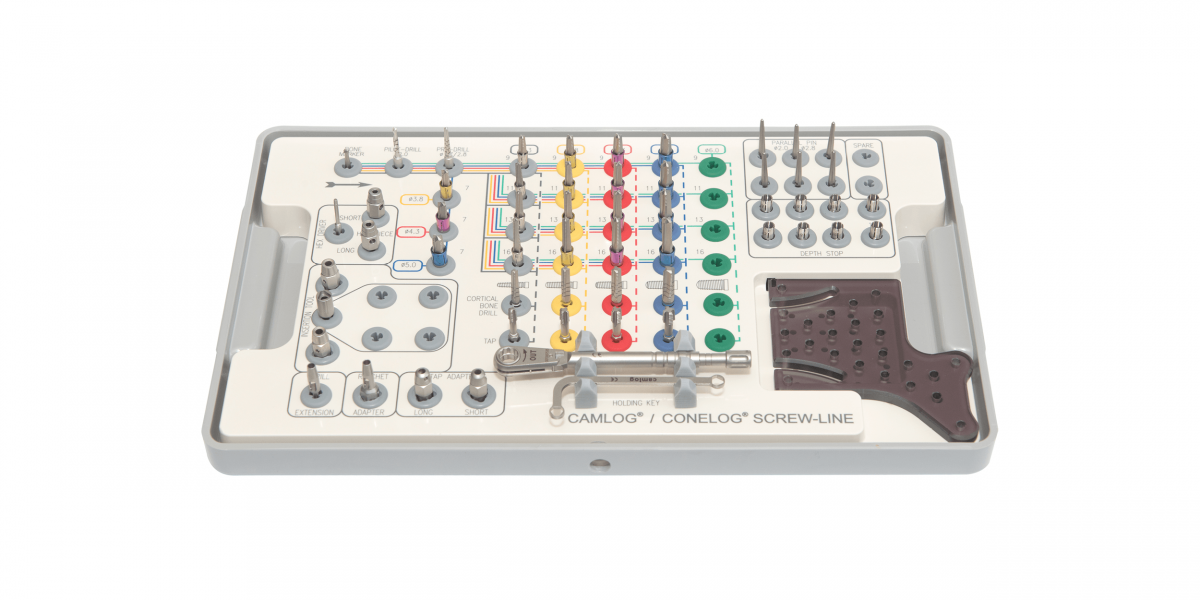

CAMLOG / CONELOG SCREW-LINE surgical kit

The CAMLOG® / CONELOG® SCREW-LINE surgical kits contain all the surgical instruments needed to form a bone socket and insert an implant. The drills are organized in the surgical kit according to the CAMLOG color-coding, according to the treatment steps. Reusable and internally cooled drills ensure trouble-free bone socket preparation. The cutting-edge geometry of the drills results in excellent cutting performance and excellent osseointegration.

CAMLOG® and CONELOG® SCREW-LINE implants (due to their identical external geometry) can be inserted with the same surgical kit.